Introduction: Listen to the voice of customers and define the direction of product evolution

In the field of industrial equipment, safety and reliability are always the core concerns of customers. Recently, our cooperation experience with a European customer once again confirmed that ” customer-centric” is not only a slogan, but also a driving force for product innovation. In response to customers’ concerns about traditional safety devices (Mechanical Lock Device), we flexibly designed the ON-7801 ultra-thin small scissor-type hydraulic lift and quickly customized a version without mechanical safety , which successfully dispelled customers’ doubts and won recognition. The following is an in-depth analysis of this case.

Pain point insights: When “security design” becomes a burden

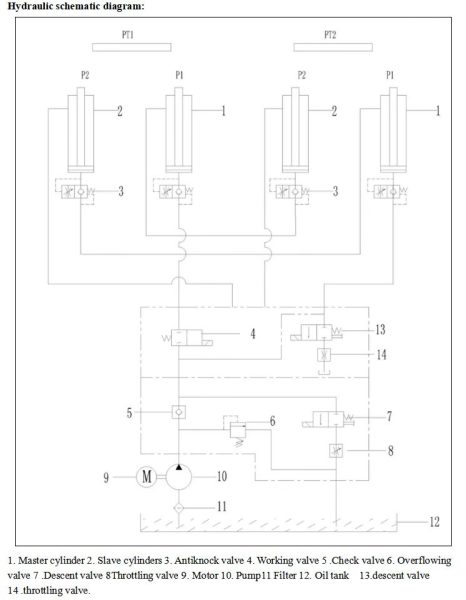

This European customer once used a certain brand of lift and clearly stated: ” XXX uses these “Mechanical lock device” and we have no good memories, very fragile. We prefer without. The master and slave cylinders provide safety.” This feedback reveals a common contradiction in the industry: although traditional mechanical lock devices are designed to improve safety, if the design is redundant or lacks durability, it will become a shortcoming of the equipment. How to simplify the structure without sacrificing safety? This is exactly our optimization direction.

Solution: No need to compromise on safety, design changes based on needs

1. There is no mechanical lock device, and a hydraulic oil circuit insurance is adopted.

2. The lift is raised to the highest position for exhaust and leveling (one-button leveling). After it is lowered, the two platforms are at the same height, and there is no need to manually operate the ball valve for exhaust and leveling.

3. The lifting height is slightly reduced. The maximum lifting height of the lift with a mechanical safety device is 1900mm, and the maximum lifting height of the lift without a mechanical safety device is 1850mm.

This case demonstrates our core strengths:

Modular design: supports adding or removing functional components as needed, and quickly adapts to different market standards;

Technology accumulation: More than 20 years of experience in research and development of the lift industry, ensuring safety redundancy and performance balance;

Global service: No matter where the customer comes from, Eounice provides precise support.

Conclusion: Your needs are the starting point of our innovation

In the fiercely competitive car lift market, there is no “one-size-fits-all” perfect solution. Only by continuously listening to the voice of customers can we create products that truly solve problems. The version without a mechanical safety device of the ultra-thin small scissor-type hydraulic lift is not only a technical upgrade, but also a model of our collaborative innovation with customers.

If you are facing similar challenges or want to customize your lifting solution, please feel free to contact Eounice. Safety is no small matter, design has no boundaries – let us explore a more efficient future together!

Call to Action :

👉Click to download ON-7801-35 technical manual: ON-7801 3.5T

👉Book a free consultation: Contact

👉Explore more customized lift models: PRODUCTS

Keywords: Car Lifts, Scissor Lift, No mechanical safety device, Hydraulic safety system, Customized solution, European market compliance